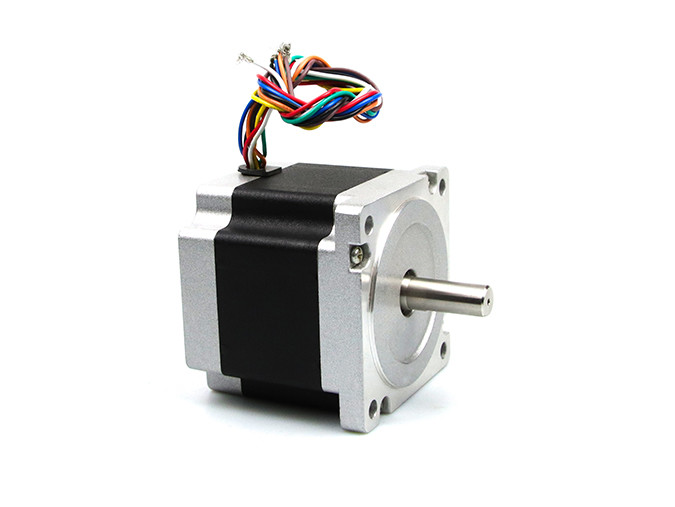

86BYGH 86mm Nema 34 Stepper Motor With Driver 4.2A 3N.M 6N.M 8N.M 12N.M Used For CNC Engraving Milling

A Nema 34 stepper motor is a stepper motor with a 3.4 x 3.4 inch (86 x 86 mm) faceplate. Nema 34 high torque stepper motors deliver great value with no quality sacrifice. These motors are engineered to provide the highest possible torque but minimize vibration and audible noise.

NEMA (National Electrical Manufacturers Association) 34 is a stepper motor with a 3.4×3.4 inch faceplate and 1.8° step angle. Each phase draws 4.0 A, allowing for a holding torque of 42 kg-cm. NEMA 34 Stepper motor is generally used in Printers, CNC machine, Linear actuators and hard drives.

The decision between NEMA 23 and NEMA 34 motors is primarily a decision about productivity -- NEMA 34 motors can remove material at a higher rate using higher feed rates and deeper cut depths.

1. 86mm Hybrid Stepper Motor Genaral Specification:

| Name |

nema 34 step motor |

| Model |

JK86HS155-4208 |

| Motor Type |

bipolar / unipolar stepper motor |

| Rated Voltage |

5.25V |

| Holding Torque |

13N.m |

| Step Angle |

1.8 degree or 1.9 degree or 1.2 degree stepping motor |

| Current |

4.2A |

| Shaft |

12.7mm / 14mm / 15.875mm |

| Shaft Type |

round shaft / D-cut shaft / Key shaft |

| Usage |

medical devices,stage lighting equipment, robot, CNC machine, music fountain and other industrial automatic equipment. |

2. 86BYGH nema 34 Step Motor Electrical Specification (1.8 degree):

| Model No. |

Step Angle |

Motor Length |

Current

/Phase

|

Resistance

/Phase

|

Inductance

/Phase

|

Holding Torque |

# of Leads |

Detent Torque |

Rotor Inertia |

Mass |

| ( °) |

(L)mm |

A |

Ω |

mH |

N.m |

No. |

Kg.cm |

g.cm2 |

Kg |

| JK86HS68-5904 |

1.8 |

67 |

5.9 |

0.28 |

1.7 |

3.4 |

4 |

0.8 |

1000 |

1.7 |

| JK86HS68-2808 |

1.8 |

67 |

2.8 |

1.4 |

3.9 |

3.4 |

8 |

0.8 |

1000 |

1.7 |

| JK86HS78-5504 |

1.8 |

78 |

5.5 |

0.46 |

4.0 |

4.6 |

4 |

1.2 |

1400 |

2.3 |

| JK86HS78-4208 |

1.8 |

78 |

4.2 |

0.75 |

3.4 |

4.6 |

8 |

1.2 |

1400 |

2.3 |

| JK86HS97-4504 |

1.8 |

97 |

4.5 |

0.66 |

3.0 |

5.8 |

4 |

1.7 |

2100 |

3.0 |

| JK86HS97-4008 |

1.8 |

97 |

4.0 |

0.98 |

4.1 |

4.7 |

8 |

1.7 |

2100 |

3.0 |

| JK86HS100-6004 |

1.8 |

100 |

6.0 |

0.36 |

2.8 |

7.0 |

4 |

1.9 |

2200 |

3.1 |

| JK86HS115-6004 |

1.8 |

115 |

6.0 |

0.6 |

6.5 |

8.7 |

4 |

2.4 |

2700 |

3.8 |

| JK86HS115-4208 |

1.8 |

115 |

4.2 |

0.9 |

6.0 |

8.7 |

8 |

2.4 |

2700 |

3.8 |

| JK86HS126-6004 |

1.8 |

126 |

6.0 |

0.58 |

6.5 |

6.3 |

4 |

2.9 |

3200 |

4.5 |

| JK86HS155-6004 |

1.8 |

155 |

6.0 |

0.68 |

9.0 |

13.0 |

4 |

3.6 |

4000 |

5.4 |

| JK86HS155-4208 |

1.8 |

155 |

4.2 |

1.25 |

8.0 |

12.2 |

8 |

3.6 |

4000 |

5.4 |

3.Electrical Specification of nema 34 round stepper motor (1.8 degree):

|

Model No.

|

Step Angle

|

Motor Length

|

Current

/Phase

|

Resistance

/Phase

|

Inductance

/Phase

|

Holding Torque

|

# of Leads

|

Detent Torque

|

Rotor Inertia

|

Mass

|

|

( °)

|

(L)mm

|

A

|

Ω

|

mH

|

g.cm

|

No.

|

g.cm

|

g.cm2

|

Kg

|

|

JK86HY62-5904

|

1.8

|

62

|

5.9

|

0.23

|

1.5

|

1.8

|

4

|

0.8

|

560

|

1.5

|

|

JK86HY94-4006

|

1.8

|

94

|

4.0

|

0.75

|

4.5

|

2.6

|

6

|

2.4

|

1100

|

2.6

|

|

JK86HY94-5604

|

1.8

|

94

|

5.6

|

0.38

|

3.9

|

3.5

|

4

|

2.4

|

1100

|

2.6

|

|

JK86HY134-6706

|

1.8

|

134

|

6.7

|

0.45

|

2

|

3.6

|

6

|

3.6

|

1800

|

3.6

|

|

JK86HY134-5604

|

1.8

|

134

|

5.6

|

0.63

|

6.6

|

5.0

|

4

|

3.6

|

1800

|

3.6

|

4.Electrical Specification of 3 phase hybrid stepping motor (1.2 degree):

| Model No. |

Step Angle |

Motor Length |

Current

/Phase

|

Resistance

/Phase

|

Inductance

/Phase

|

Holding Torque |

Rotor Inertia |

Mass |

| ( °) |

(L)mm |

A |

Ω |

mH |

N.m |

g.cm2 |

Kg |

| JK86H3P65-3006 |

1.2 |

65 |

3.0 |

0.5 |

1.6 |

2 |

1100 |

1.65 |

| JK86H3P98-5206 |

1.2 |

98 |

5.2 |

0.6 |

3 |

4.5 |

2320 |

2.70 |

| JK86H3P113-5206 |

1.2 |

113 |

5.2 |

0.9 |

5.9 |

6 |

3100 |

3.50 |

| JK86H3P126-6006 |

1.2 |

126 |

6.0 |

0.75 |

2.4 |

6 |

3300 |

3.80 |

| JK86H3P150-5006 |

1.2 |

150 |

5.0 |

1.5 |

3 |

7 |

4650 |

5.10 |

5.Electrical Specification of nema 34 closed loop stepper motor:

| Model No. |

Step Angle |

Motor Length |

Current

/Phase

|

Resistance

/Phase

|

Inductance

/Phase

|

Holding Torque |

# of Leads |

Detent Torque |

Rotor Inertia |

Mass |

| ( °) |

(L)mm |

A |

Ω |

mH |

N.m |

No. |

Kg.cm |

g.cm2 |

Kg |

| JK86HSN45 |

1.8 |

78 |

6 |

0.27 |

2 |

4.6 |

4 |

1.2 |

1400 |

2.3 |

| JK86HSN65 |

1.8 |

100 |

6 |

0.27 |

2.2 |

6.8 |

4 |

1.9 |

2200 |

3 |

| JK86HSN85 |

1.8 |

115 |

6 |

0.36 |

3.8 |

8.5 |

4 |

2.4 |

2700 |

4.3 |

| JK86HSN120 |

1.8 |

155 |

6 |

0.44 |

3.8 |

12 |

4 |

3.6 |

4000 |

5.9 |

6.Electrical Specification of 86mm 3N.m 6N.m brake for step motor:

| Model No. |

Step Angle |

Motor Length |

Current

/Phase

|

Resistance

/Phase

|

Inductance

/Phase

|

Holding Torque |

# of Leads |

Detent Torque |

Rotor Inertia |

Mass |

| ( °) |

(L)mm |

A |

Ω |

mH |

N.m |

No. |

Kg.cm |

g.cm2 |

Kg |

| JK86HS68-5904BK6 |

1.8 |

67 |

5.9 |

0.28 |

1.7 |

3.4 |

4 |

0.8 |

1000 |

1.7 |

| JK86HS78-5504BK6 |

1.8 |

78 |

5.5 |

0.46 |

4 |

4.6 |

4 |

1.2 |

1400 |

2.3 |

| JK86HS97-4504BK6 |

1.8 |

97 |

4.5 |

0.66 |

3 |

5.8 |

4 |

1.7 |

2100 |

3.0 |

| JK86HS100-6004BK6 |

1.8 |

100 |

6.0 |

0.36 |

2.8 |

7.0 |

4 |

1.9 |

2200 |

3.1 |

| JK86HS115-4204BK6 |

1.8 |

115 |

4.2 |

1.2 |

14 |

8.7 |

4 |

2.4 |

2700 |

3.8 |

| JK86HS126-6004BK6 |

1.8 |

126 |

6.0 |

0.58 |

6.5 |

6.3 |

4 |

2.9 |

3200 |

4.5 |

| JK86HS155-6004BK6 |

1.8 |

155 |

6.0 |

0.68 |

9.0 |

13 |

4 |

3.6 |

4000 |

5.4 |

7.Electrical Specification of nema 34 linear screw:

| Screw Diameter(mm) |

Screw Lead(mm) |

Screw Pitch(mm) |

Travel per step(mm) |

Screw Diameter(mm) |

Screw Lead(mm) |

Screw Pitch(mm) |

Travel per step(mm) |

|

Tr10

|

2 |

2 |

0.01 |

Tr12

|

2 |

2 |

0.01 |

| 3 |

1.5 |

0.015 |

3 |

3 |

0.015 |

| 4 |

2 |

0.02 |

8 |

2 |

0.04 |

| 8 |

2 |

0.04 |

10 |

2 |

0.05 |

| 10 |

2 |

0.05 |

/ |

/ |

/ |

| 12 |

2 |

0.06 |

/ |

/ |

/ |

8. 1.8 degree nema 34 step motor Dimensions: (Unit=mm)

9. hybrid stepper motor shaft Dimensions: (Unit=mm)

10.Customized design of cnc stepper motor kits:

11.Different shaft type:

12.Advantages of 86BYGH step motor

- Low cost for control achieved

- High torque at startup and low speeds

- Ruggedness

- Simplicity of construction

- Can operate in an open loop control system

- Low maintenance

- Less likely to stall or slip

- Will work in any environment

- Can be used in robotics in a wide scale.

- High reliability

- The rotation angle of the motor is proportional to the input pulse.

- The motor has full torque at standstill (if the windings are energized)

- Precise positioning and repeatability of movement since good stepper motors have an accuracy of 3–5% of a step and this error is non-cumulative from one step to the next.

- Excellent response to starting/stopping/reversing.

- Very reliable since there are no contact brushes in the motor. Therefore, the life of the motor is simply dependent on the life of the bearing.

- The motors response to digital input pulses provides open-loop control, making the motor simpler and less costly to control.

- It is possible to achieve very low-speed synchronous rotation with a load that is directly coupled to the shaft.

- A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses.

13.Applications of step motors:

As the stepper motor are digitally controlled using an input pulse, they are suitable for use with computer controlled systems.

They are used in numeric control of machine tools.

Used in tape drives, floppy disc drives, printers and electric watches.

The stepper motor also use in X-Y plotter and robotics.

It has wide application in textile industries and integrated circuit fabrications.

The other applications of the Stepper Motor are in spacecrafts launched for scientific explorations of the planets etc.

These motors also find a variety of commercial, medical and military applications and also used in the production of science fiction movies.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!